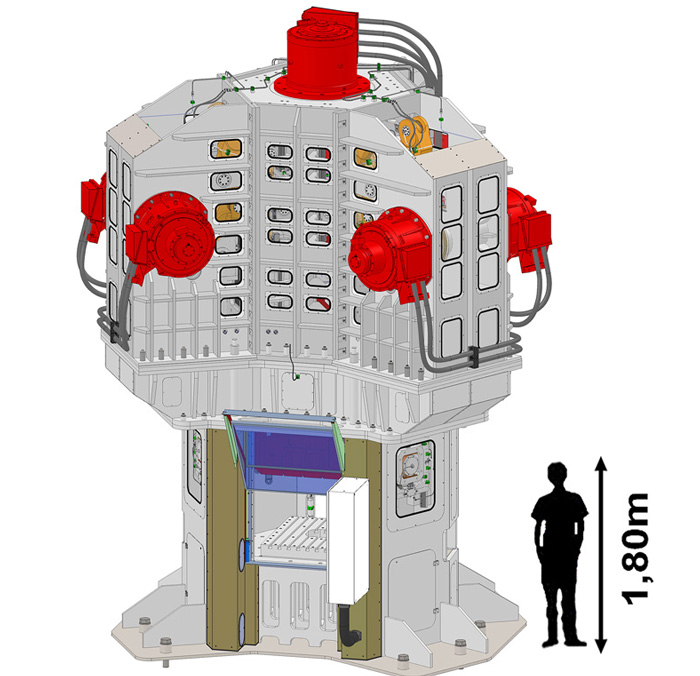

The 3D Servo Press is a servo press with three degrees of freedom in the ram, which was developed at PtU. The 1600 kN version has the same characteristics as the 3D servo press with 10 kN pressing force.

By means of a flexible ram movement with several degrees of freedom, the press enables unique possibilities for application which will be used especially in massive forming. The ram is moved at three points by three drive systems, each consisting of two servo motors and a crank mechanism.

The drive systems can be controlled independently of one another, whereby the translation of the tool center point (TCP) in the z-direction and the rotation about the x- and y-axis can be realized freely. In addition to this innovation, the drive mechanisms are capable of carrying out high stroke rate, as is commonly known for conventional mechanical presses with only one degree of freedom.

Technical data

- 6 servo drives

- 2 spindle drives

- Press force: 1600 kN

- max. stroke rate: nmax 200/min

- max. stroke at nmax 100 mm

- max. stroke combined: 300 mm

- press bed width: 1000 mm

- press bed depth: 1000 mm