The pneumatic press is double-acting and has an additional, controllable fluid-support. Depending on the tool-concept, the actor-units with four pneumatic-cylinders each (4 mm x 80 mm and 4 mm x 125 mm in diameter) can be combined with the fluid-support.

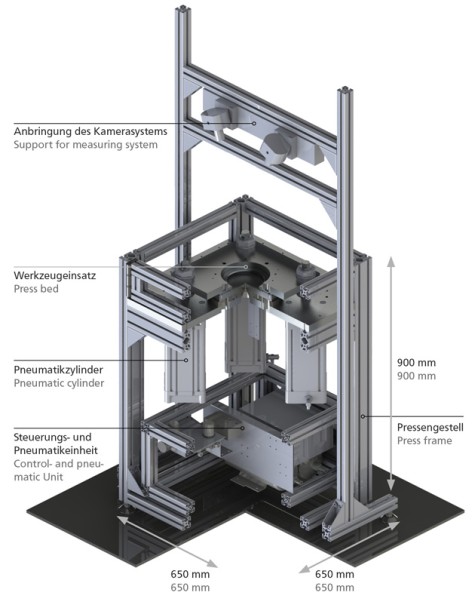

With the used proportional pressure regulator, the pressure can be controlled up to a maximum pressure of 10 bar. The press is used for the fluid-based forming and biaxial material characterization of fiber-materials, fiber-based sandwich materials and thin metal sheets in particular. Additionally, these materials can be deep-drawn in a standard cup drawing tool. All tool components can be heated. With the designed LabVIEW control software, the press is intuitively operable. The compact press has the dimensions of about 650 mm x 650 mm x 900 mm. The formed specimens can have diameters up to 200 mm.

Technical data

- 2 pneumatic cylinders (diameter 80 mm / 125 mm)

- 1 fluid support (pressure controlled)

- Pressing Force: 40 kN

- Accuracy: 1 % of maximum pressure (2 bar / 6bar / 10bar)

- Max. specimen size: 200 mm

- Press bed width: 300 mm

- Press bed depth: 300 mm