Experimental investigations of deep- and stretch drawing processes are difficult to be evaluated in real tools used for industrial sheet metal forming. Hence, the strip-drawing test is a common method to analyze these processes.1

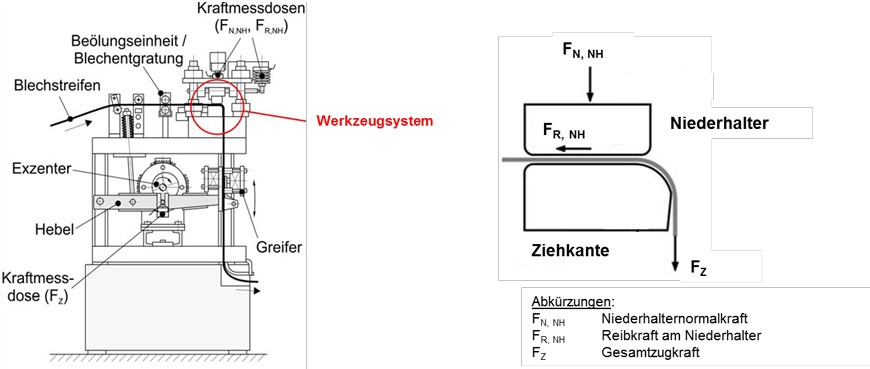

The strip drawing allows for simulating real deep drawing and stretch forming conditions and its tribological behavior. For tribological analysis of wear behavior, a strip drawing test setup with blank holder and circular deflection is utilized. This test setup is used to reproduce the friction conditions caused by bending in the beginning of the drawing edge.

Test details

In this setup, a 20 mm wide deburred metal strip passes a modular tool set consisting of drawing edge and blank holder, loaded by a constant force FN,BH. The strip is bent by 90° at the radius of the drawing edge. The measured variables are: blank holder force FN,BH, friction force FF,BH, and tensile force FT.

Technical data

- Strip width: 20 mm

- Blank holder area: 100 to 400 mm²

- Lubricant amount: 0.2 to 5 g/m

- Contact normal pressure: 1 to 50 N/mm²

- Sliding speed: till 200 mm/s

- Sliding distance per hub: 25 mm

1 Groche, P.; Filzek, J.; Nitzsche, G.: Local contact conditions in sheet metal forming and their simulation in laboratory test methods. In: Annals of the German Academic Society for Production Engineering XI/1, Nr. 1. Braunschweig, 2004.