“Machine Hammer Peening” and “Deep Rolling” are processes for the mechanical surface treatment of a work piece. The objective of this process is to induce compressive residual stresses in the surface layer, to achieve strain hardening, to increase the hardness of the surface layer and/or to manipulate the topography of the work piece.

“Machine Hammer Peening”

During “Machine Hammer Peening”, a carbide ball is cyclically accelerated against the surface of the workpiece. The most decisive characteristic of the process is the energy input into the work piece which is provided by the kinetic energy of the moving mass. The systems can be driven either electromagnetically or pneumatically. The working frequency can be selected between 20 Hz and 500 Hz. Both systems from Accurapuls (electromagnetic) and 3S-Engineering (pneumatic) are available at the Institute for Production Engineering and Forming Machines.

“Deep Rolling”

The process of “Deep Rolling” is characterized by a carbide ball that is constantly pressed against the surface of the workpiece by a hydraulic pressure. The ball is hydrostatically mounted in a ball socket. With the help of a hydraulic unit, a lubricant pressure of up to 400 bar can be generated.

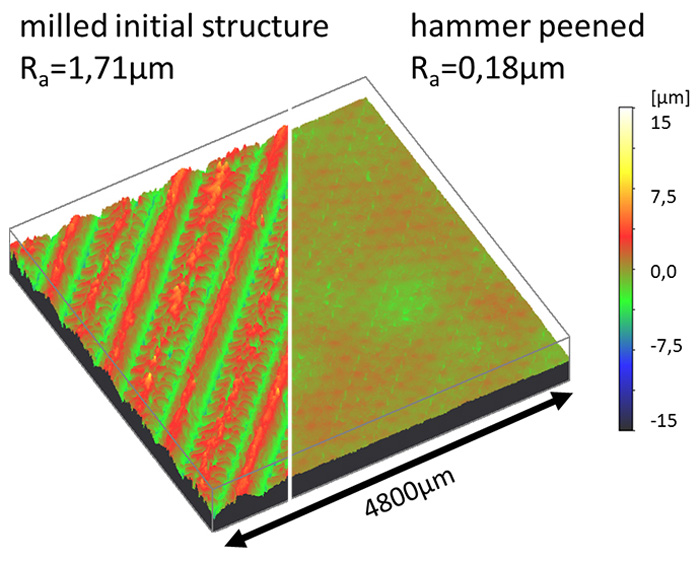

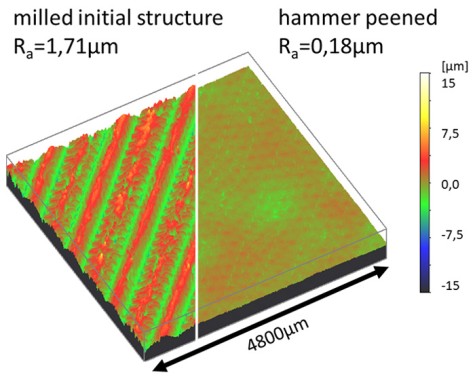

Besides the after-treatment of welding seams and cyclically loaded parts (due to the induction of compressive residual stresses) the systems can be used in tool and mold production. Therby, a significant part of the manual polishing process can be substituted by the mechanical smoothing of the surface asperities (see Figure).