The combined strip drawing facility is used for experimental investigation of tribological conditions in sheet metal forming processes, especially during deep drawing and stretch forming. For this purpose, there are various testing modes of the strip drawing test that simulate certain conditions of deep drawing and stretch forming operations.

The test stand has an expansive and precise force measurement technology. In addition, the test contains an extensive periphery which guarantees reproducible testing conditions by an optional cleaning and lubricating unit of the used sheet metal and at the same time a high degree of automation.

For the experimental procedure, single sheet metal strip as well as coil material can be used.

Testing modes

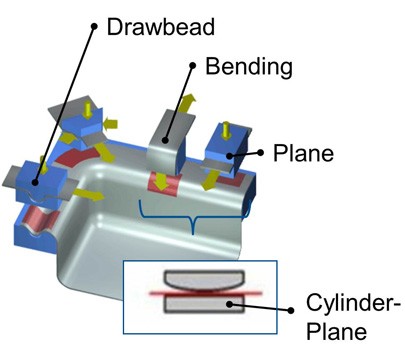

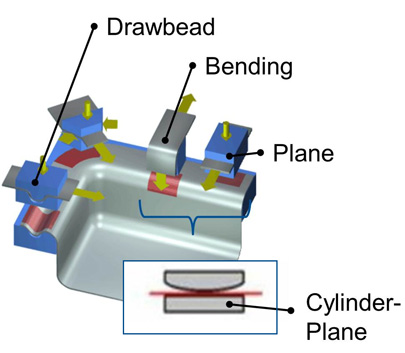

The combined strip drawing facility allows friction and wear tests. Toolsets with drawbead, cylinder-plane, or plane geometry are used for these tests.

Technical data

- Strip width: 30 mm – 50 mm

- Thickness: 0.5 mm – 2.5 mm

- Automated single sheet metal strips or coil operation

(Single sheet lengths: 800 to 2000 mm) - optional cleaning and lubrication

- Draw rate: variable up to max. 100 mm/s