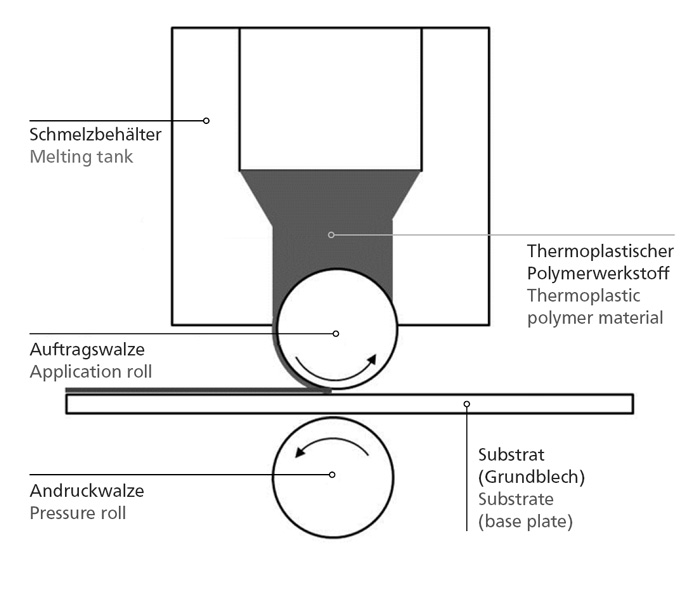

The Hotmelt Coating Machine is used for coating flat substrates with hotmelt.

The substrate to be coated is passed between pressure and application rollers, which are driven in opposite directions at a desired speed. The upper part of the application roll immerses into the lower opening of the melting tank and then transfers the heated and therefore liquid thermoplastic polymer material onto the substrate.

Technical data

- Maximum coating width: 300 mm

- Material application roller: tempered steel

- Pneumatically operated contact pressure roller

- Electronically controlled hotmelt temperature