The ultrasonic test instrument USD 15 SX from Krautkramer (today GE Inspection Technologies GmbH) is an instrument used for so called A-Scans.

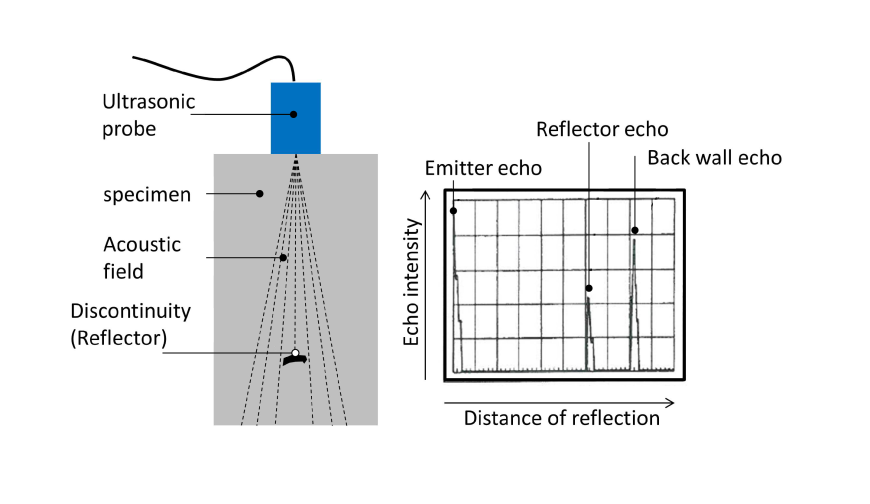

A-Scans are used for classical imperfection detection (Figure 2), the examination of welds or the measurement of sheet thicknesses. The position of imperfections is acquired by evaluation of the time difference between the reflector echo and the echo from the back wall. The distance of the back wall echo is usually known due to the component geometry.

The depth of detectable defects is limited by the acoustic attenuation which depends on the investigated material. In general, the attenuation of steel is less than that of polymers. The minimum sheet thickness which can be measured depends on the wave length which is given by the specific frequency of the transducer in use. The verifiable thickness varies between a half and a third of the wavelength. Thus, thin sheets require high frequencies which, however, lead to a rise in acoustic attenuation. Therefore, an appropriate transducer has to be chosen for each examination task.

Technical data

- 15 MHz vertical transducer at the institute available

- Use of angle transducer possible

- Device available for transducer with a frequency range of 0.2 – 35 MHz

- Adjustable acoustic velocity between 500 and 15000 m/s

- Pulse repetition frequency between 1 and 12000 Hz (for continuous measurements)

- 3 individual adjustable aperture for echo analysis

- Automatic time difference analysis for imperfection depth determination