With the powerful thermal imaging system ThermoView TV40, temperatures become visible. The functionality of the thermal camera is based on the infrared radiation emitted by surfaces, which, depending on the intensity, is converted into a thermal image by means of the ThermoView software. The associated ThermoView software enables sophisticated analyses as well as comprehensive temperature control of processes and components.

Since the intensity of the emitted infrared radiation is significantly influenced by the material properties of the sample, component defects such as cavities and cracks can also be detected. Component defects such as blowholes or cracks influence the heat flow. Depending on the examination method (transmitted radiation or reflected radiation, see Figure 2), component defects on the surface are recognisable as heat sources or heat sinks. This situation is used for volumetric defect detection.

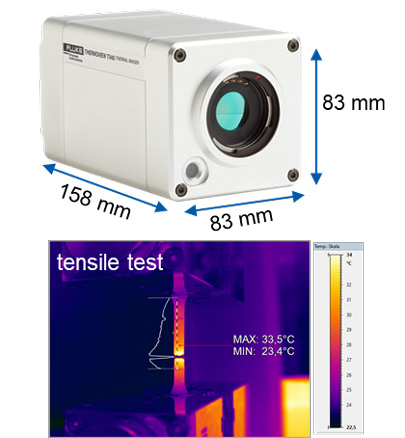

Technical data

- Temperature range: -10 to 1200°C

- Measuring accuracy: ±2°C or ± of measured value

- Infrared resolution: 320 x 240 or 640 x 480 pixels

- Spectral range : 8 to 14 µm

- Detector: Focal plane array (FPA) without cooling

- Focal range: IR 15 cm to ∞

- Frame rate: 60 frames/second

- Emission correction: 0.10 to 1.00

- Location: stationary or mobile use