Since April 2014, a new laser machining center has been at PtU's disposal. A YLS-3000-S2T laser of the company IPG serves as beam source.

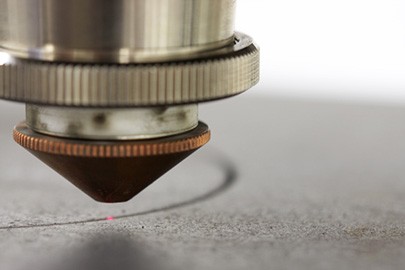

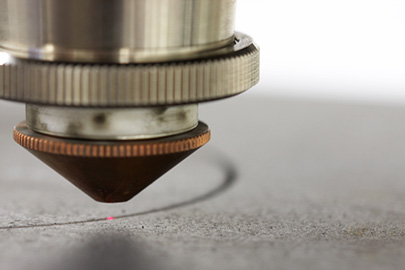

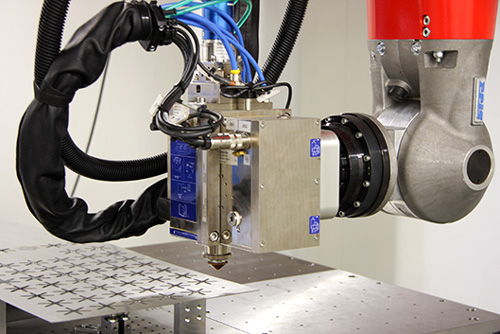

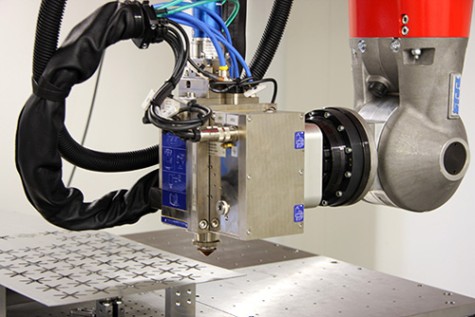

Beam guidance to the HP SSL Plus cutting optics and to the Modular Welding Optics AP44 (MWO44) for welding operations is carried out by means of an optical fibre. The processing optics are guided by an RLP16-26 gantry system from Reis Robotics. The six axes of the portal system allow machining at any position, which can take place in two operating modes. The first operating mode is intended for geometrically flexible welding and cutting operations in research mode and requires complete closure of the housing. In mode II, the laser can be used with the cabin feedthroughs open in the split-forming line for integral joining of branched sheets or for heat treatment.

As part of a major refurbishment of the laser machining center in 2022, the laser power was increased to 4,000 watts. A cold wire feeder and weld tracking system were installed for the welding optics. Supplemented by an improved protective and process gas supply system, more complex and also completely new processes can now be implemented on the laser machining center. In particular for the processing of high-strength aluminum materials, the laser processing center now offers all possibilities. The integration of a modern radiation protection system using LaserSpys additionally rounds off the modernization.

Processing optics

- Modular Welding Optics AP44 (MWO44)

- HP SSL Plus cutting head

Periphery/Components

- Reis laser gantry RLP16-26 (6 axes)

- Fiber optic cable

- Cutting and shielding gas supply

- Scansonic weld seam tracking

- Dinse cold wire feeder

Technical data

- Power: 4,000 W

- Beam parameter product: 3.5 mm*mrad (100 µ fiber) and 7.5 mm*mrad (200 µ fiber)