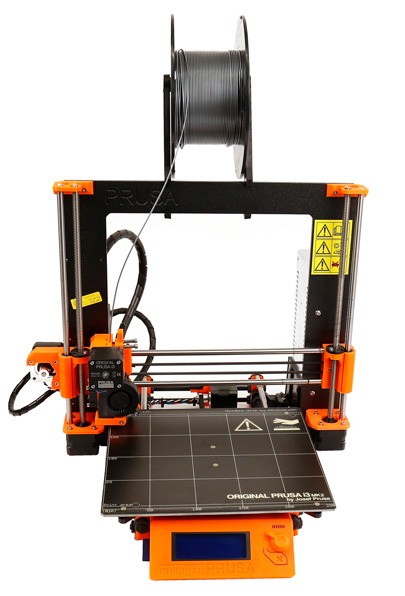

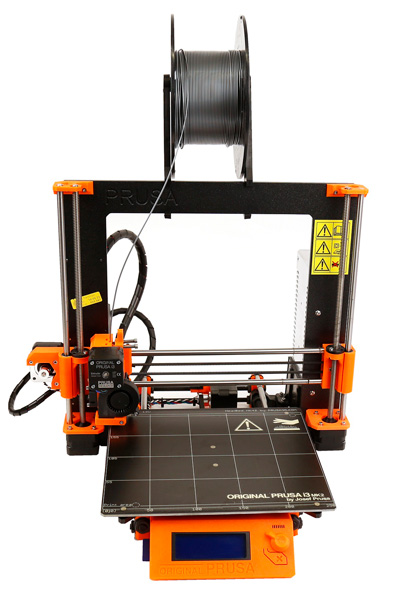

The PtU is equipped with two Prusa i3 MK2S printers, one of which is able to print four different materials simultaneously thanks to the Multi Material Upgrade. The integration of the OctoPrint Web Interface allows the control and monitoring of the printing process.

Due to the possibility of short-term and resource-saving production of components, student projects and research work benefit in terms of saving time, flexibility and investigation opportunities. The printers are mainly used for the production of auxiliary equipment and prototypes, e.g. for testing functionality and assembling. But also forming tools with high load (e.g. inlay for hydroforming die) were successfully produced.

Technical data

- Printing method: Fused Deposition Modeling (FDM)

- Print volume: 250 mm x 210 mm x 200 mm

- Nozzle diameter: 0.4 mm

- Vertical resolution: minimum layer thickness 0.05 mm

- Applicable materials: PLA, PETG, PET etc.