The pneumatic bulge test (pbt) is a test for material characterization which is designed in the style of Panknin's hydraulic bulge test.

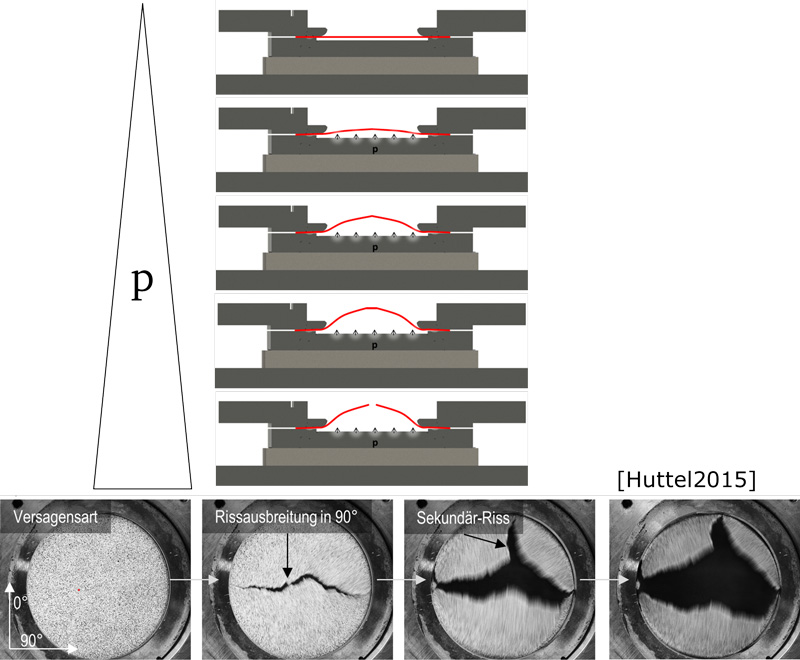

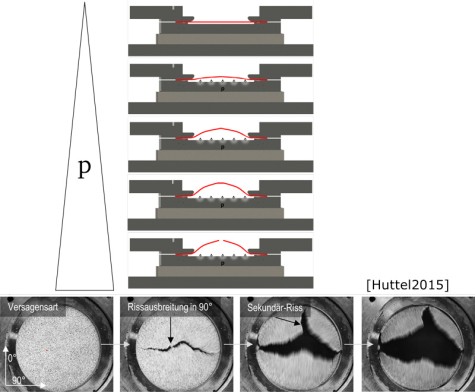

With this test, a flat and rotational symmetric specimen is clamped at the circumference, which suppresses the material flow during the next test steps. In the next step a continuously increasing pressure is applied on the bottom side of the specimen, which begins to bulge. When the bursting pressure is reached, the specimen cracks and the test is finished. While the pressure is applied and the specimen is bulging, the surface of the sample is observed by a special stereo-camera system. With this system, the surface strain is measured. Assuming volume constancy, flow curves can be calculated. As a result of the clamped specimen edges and the in-plane extension, a biaxial state of stress is formed in the tested material.

In particular, the pneumatic bulge test is used for characterization of fiber based materials and thin-metal sheets, which have a lower bursting pressure. The main benefit of a pneumatic bulge test in comparison to a hydraulic system is the higher accuracy at low pressure values. A pressure accuracy of 1% at a maximum pressure of 2, 6 or 10 bar is accessible. The specimens diameter is 200 mm.