„ProTool WearDetect“ – Development of a method for the detection of wear conditions in multi-stage sheet metal forming processes

The aim of the research project is to investigate the development of wear in multi-stage forming processes and to implement automated wear monitoring. With the use of the newly developed system for real-time wear detection, users can react immediately to temporary signs of wear and counteract them. This avoids large amounts of scrap and reduces costs for tool downtime and repairs. In addition to users, manufacturers of lubricants also receive data-supported insights into the performance of their lubricants in long-term tests. This enables specialised companies to provide their customers with targeted advice and, if necessary, to implement inline wear monitoring.

Coordinator: Jonas Moske M. Sc.

Duration: November 2022 – October 2024

Funded by: LOEWE 3

Motivation

In sheet metal processing, wear phenomena have a direct influence on the geometric and functional product properties and thus directly affect the economic efficiency of such processes. Thus, the systematic research of tool wear and its effect on the process is interesting for companies for technological and economic reasons.

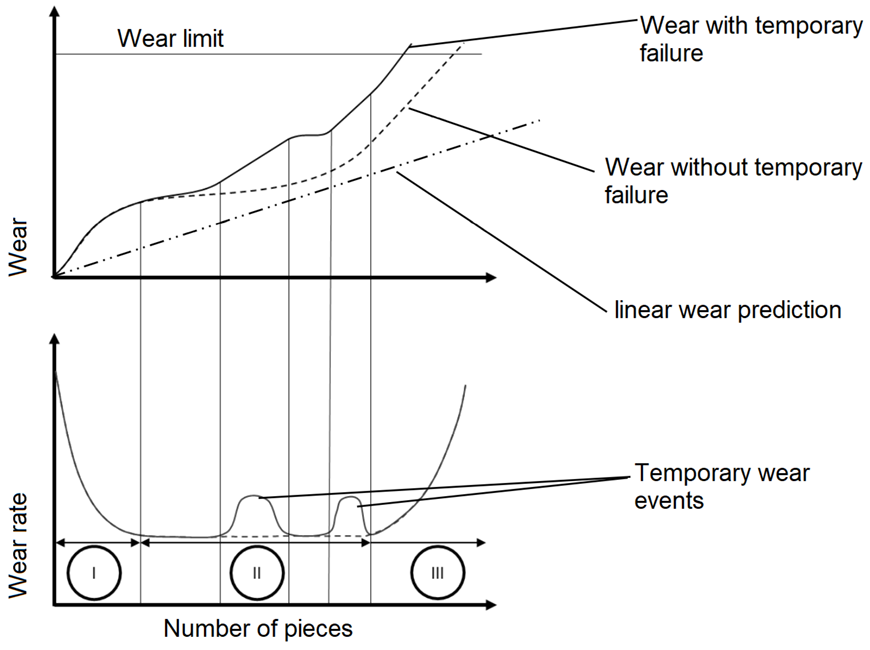

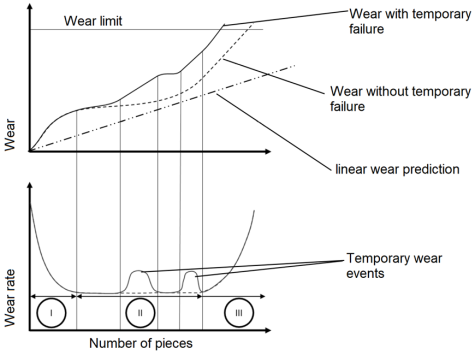

For reasons of lightweight construction, the progressive use of high-strength materials (e.g. certain aluminium alloys) as well as the processing of copper, brass and nickel in the context of digitalisation and electrification are also of interest. Aluminium is increasingly used in car body construction and copper for electrical components. Both materials have a much stronger tendency to adhesion than steel materials and can therefore cause adhesive wear more quickly. In addition to continuous wear, small fluctuations in process parameters can have a major impact on wear conditions (see Figure 1). Sudden occurrences of transient adhesive wear can unexpectedly increase the wear rate and affect the quality of a product batch. This effect plays a particularly important role in multi-stage processes in progressive dies, since the close interlinking of the individual processes means that the consequences of temporary wear in a die stage are not only spatially limited to that die stage. Rather, wear and quality deficiencies in one stage can also have a negative impact on the following stages. A continuous analysis of the wear condition of component and tool can directly inform the user about possible temporary wear or wear conditions. Here, a combination of optical surface measurement and sensor-based analysis of individual process parameters (e.g. force and temperature curve) should provide more precise findings. In this way, corrective measures can be taken promptly to reduce maintenance-related downtimes and rejects to a minimum. Furthermore, this approach enables tighter tolerances to be maintained and also improves the surface quality of the components.

Approach

The analysis shows that previous approaches to dealing with wear in sheet metal forming have considerable deficits. On the one hand, empirical formulas are used for rough design, on the other hand, in the industrial environment, wear phenomena are measured on the workpiece and less on the tool. This monitoring takes place, for example, in light cabins where the components are assessed under special illumination by experienced employees While analytical approaches can be used to estimate tool lifetimes a priori, the prediction of temporarily limited wear events as well as the granular description of the current wear phenomenon s and its localisation on the tool are not successful. The research project assumes that grey-box models can be established with the help of inline recorded process variables and known white-box models, which enable a far more detailed description of current wear phenomena. The focus here is on combining analytical approaches with data-driven models, such as machine and deep learning, to map precisely these real wear conditions. The core of the research approach to be pursued is a central database that enables the central management of sensor-based process variables and digitised surfaces as well as the integration of data-driven models. The application of the combination of analytical and numerical models to real forming processes and their feedback results in an iterative procedure for the development of the wear models. In particular, by optically recording the tools and their wear-related geometry changes, it should be possible to build up geometric tool parameters with the help of numerical simulation. Fraunhofer IGD is developing a laser-based measuring system to record the geometric changes precisely, quickly and automatically.

Acknowledgement

The research work presented here takes place within the framework of the IGF project no. N04434/21 of the research association Europäische Forschungsgesellschaft für Blechverarbeitung e.V. (EFB).

This is funded by the German Federal Ministry of Economics and Climate Protection (BMWK) through the German Federation of Industrial Research Associations (AiF) as part of the programme for the promotion of joint industrial research (IGF) on the basis of a resolution of the German Bundestag.

Furthermore, we would like to thank all industrial partners who support the research project “Development of a method for the detection of wear conditions in multi-stage sheet metal forming processes using in-situ recorded process variables ” in the project-accompanying committee:

- Chemische Werke Kluthe GmbH

- Seidel GmbH & Co.

- RAZIOL Zibulla & Sohn GmbH

- Thomas GmbH

- KODA Stanz- und Biegetechnik GmbH

- Hans Berg GmbH & Co. KG

- Filzek TRIBOtech

- Hubert Stüken GmbH & Co. KG

- thyssenkrupp Rasselstein GmbH

- Tata Steel Nederland Technology B.V.

- evopro systems engineering AG

- Nidec SYS GmbH

- Zeller+Gmelin GmbH & Co. KG

- SCHEUERMANN + HEILIG GmbH

- Automotive Center Südwestfalen GmbH

Funded by

Project Partner