ROTAFLEXEXPERT

New applications for rotary swaging thanks to sensor technology and data evaluation

2025/02/04

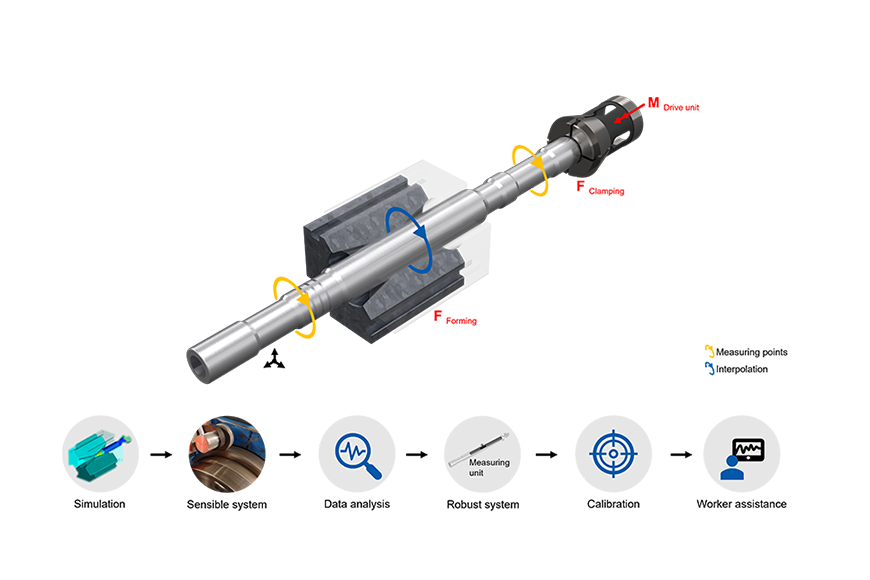

Nick Philippi takes over the ROTAFLEXEXPERT project. The project is investigating the real-time recording of process variables during rotary swaging near the forming zone. The measurement system derived from this enables process optimisation with regard to economic, technical and resource-saving objectives. The knowledge gained opens up a technological leap towards the individualised forming of rotationally symmetrical components.

Due to the strongly experience-based design and testing through many trial-and-error cycles, rotary swaging processes are currently only economical for large series. A better understanding of the process can open up the process for many applications. In a first step, simulations and practical tests will be used to implement a highly sensitive measuring system for recording the rotary feed angle – a decisive process variable. The sensitive system supports the design of a robust sensor mandrel that can record measurement data with sufficient accuracy even under production conditions in a permanently harsh environment. This research will result in a model for describing rotary swaging processes that will support industrial operations in the future.