RofoInRichtungKI – Roll forming with smart profile straightening through the development of process-specific AI models

In the research project RofoInRichtungKI (Roll forming with intelligent profile straightening through the development of process-specific AI models), an intelligent straightener is being developed in cooperation with Dreistern GmbH & Co. KG, that will support specialists in the adjustment of straightening processes, which up to now have been strongly based on experience. This intelligent straightener detects profile errors on the basis of process data and assigns the correct straightening roll positioning to them on the basis of models.

Coordinator: Johannes Hofmann M. Sc.

Duration: September 2023 – August 2025

Funded by: Zentrales Innovationsprogramm Mittelstand (ZIM) and Federal Ministry for Economic Affairs and Climate Action (BMWK)

Motivation

During roll forming, process-related longitudinal residual stresses occur which, depending on the profile geometry and load behavior of the tool rolls, lead to undesirable curvatures in the horizontal and vertical directions as well as torsions. In order to ensure that the dimensional accuracy of finished profiles is maintained, the roll forming process is followed by a straightening process. Today, the straightening parameters are set on the basis of the experience of the system operators by checking the final component geometry.

The unstable personnel situation due to the shortage of skilled workers and demographic change in Germany is a challenge for the adjustment of analog, experience-based processes such as the straightening of roll-formed profiles. This conflict is further intensified by tighter defect tolerances and an increasing complexity of the manufactured profiles as a result of increasing quality demands of the customers. For this reason, this research project will investigate the use of AI methods based on process data for assisted decision-making by skilled professionals for the straightening of roll-formed profiles.

Approach

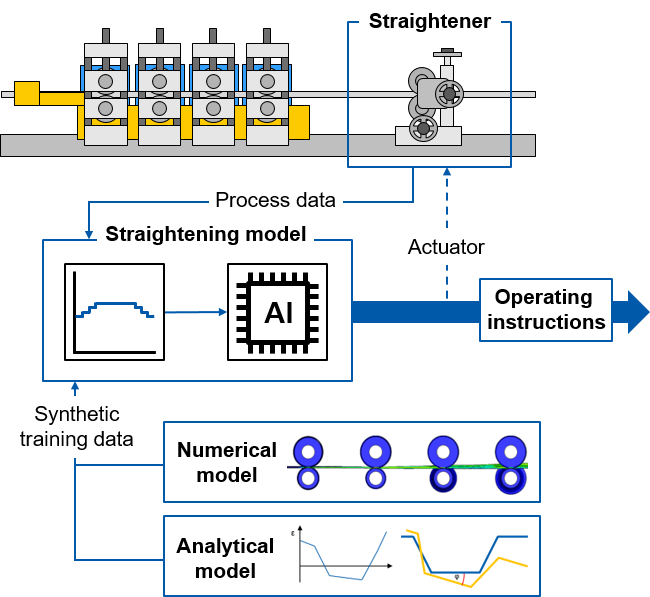

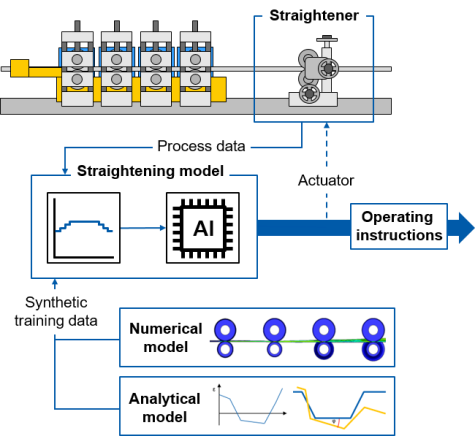

The project focuses on the development, manufacturing and validated industrial use of the intelligent straightener. For this purpose, analytical, numerical and experimental investigations are interlinked as shown in Figure 1. Analytical calculations form the basis of a numerically straightening model, with which the necessary actuating variables of the straightener as well as the occurring forces can already be calculated at the beginning of the project. These calculations are validated by experimentally recorded process data and iteratively approximated to the real process by increasing the complexity and including the forming history of the roll forming process. The data sets resulting from the simulations, in combination with the recorded and labeled process data, form the basis for the training and validation process of the straightening model. This provides the positioning of the straightening rolls as model output and can thus provide guiding support for specialists in the adjustment of the straightening process. The functionality of the intelligent straightener built in this way is validated in long-term tests in an industrial environment.

Acknowledgement

The RofoInRichtungKI project is funded by the German Federal Ministry of Economics and Climate Protection (BMWK) as part of the Central Innovation Program for Medium-Sized Businesses (ZIM). Additional thanks go to the project partner Dreistern.

Funded by

Project Partners