Tool life span estimation – Effective model test for tool life span estimation

In modern forming, tool wear is increasingly becoming a challenge due to the use of high-strength and ultra-high-strength steel. The increased stress between tool and work piece leads to reduced life of the forming tool. Therefore, it is necessary to find out a method to estimate the tool life. Within this research project, a procedure for characterising the wear resistance of a tribological system for real forming processes such as ironing and gear processing.

Motivation

A better understanding and control of tool wear are key factors for efficient sheet metal processing in small and medium-sized enterprises (SMEs). Model tests, such as strip drawing tests, offer the possibility to evaluate the wear resistance of forming tools in certain tribological systems. However, model tests cannot effectively represent the wear development or tool life in a real forming process. Therefore, an investigation of the consistency of the wear development between model test and real process is desirable.

The aim of the project is to develop a method for predicting tool life and wear development in real forming processes through a model test. In addition, the tool lives under increased load levels are determined in a model test. In addition, the tool lives under increased load levels are determined in a model test. This serves the purpose of examining, whether the actual tool life can be approximated by tests at higher tribological load levels.

Approach

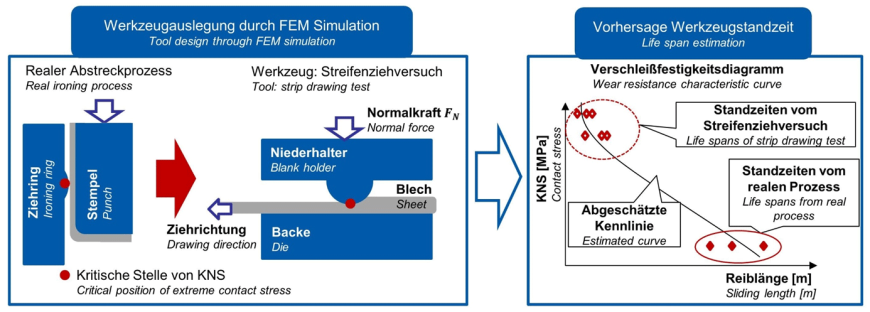

At the beginning of the project, the tribological loads in the real forming process, such as normal contact stress and temperature field in the forming tool, have been determined through FEM simulation. By selecting suitable wear models, the wear development has been determined. Based on the results of tribological loads and estimated wear development, a specific tool has been designed for model tests, which is used to illustrate the actual wear development in model tests. After the manufacturing of the designed tools, the lifetime of the tool is determined in the model test under process-similar as well as elevated load levels. The determined tool life and its scatter form the wear resistance diagram, which represents the expected values of the tool life and its uncertainties. Finally, an estimation procedure is developed so that the wear resistance characteristic curve can be derived under the entire load level (See Figure).

Acknowledgement

The research work presented here takes place within the framework of IGF project No. 21116 N of the research association Europäische Forschungsgesellschaft für Blechverarbeitung e.V. (EFB). This is funded by the Federal Ministry for Economic Affairs and Climate Action via the German Federation of Industrial Research Associations (AiF) as part of the program for the promotion of joint industrial research (IGF) on the basis of a resolution of the German Bundestag.

Furthermore, we would like to thank all industrial partners who support the research project “Prediction of tool life” in the project accompanying committee.

Funded by

Project Partners