SPP2183 – Closed loop property controlled forming processes – Multi-variable closed-loop control with feedforward control of forming product properties – Fundamentals and application to punch-hole-rolling

The aim of the priority program is to investigate the scientific basis of process-integrated property control of forming processes and to test and validate new approaches to property control.

Coordinator: Daniel Spies M. Sc.

Duration: January 2021 – December 2025

Funded by: DFG SPP2183

Motivation

Current scientific and industrial research is aimed at higher levels of automation of production processes. This form of automation focuses on the control of product properties instead of controlled process or machine variables. Besides the striving for a higher level of automation, the desire for a more efficient use of resources requires new concepts of process control in forming technology. Forming processes are often used for the production of highly loaded components due to the resulting advantageous work piece properties. As the strength of steel and aluminum materials increases, the quality of their lightweight construction increases, but at the same time the permissible process windows are also reduced. This increases the influence of semi-finished product and process fluctuations on process stability. Thus, the challenge for the design of future forming processes is to ensure a constant product quality under fluctuating process conditions.

Approach

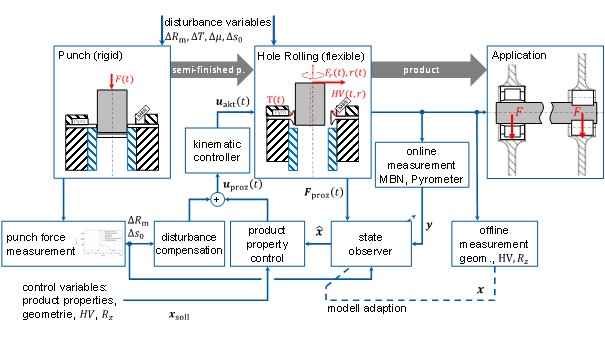

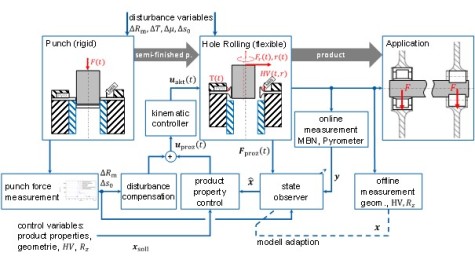

Within the subproject the basics of multi-variable closed-loop control of forming generated product properties with disturbance feedforward control are investigated by means of punch-hole-rolling. For the execution of the project, a property-controlled, novel forming process including control of hardness and geometry is implemented and developed. The validation of the control concept is based on the example process of punch-hole-rolling. By means of sensors integrated in the tool and the use of order-reduced models, material properties and geometry are recorded online. These then serve as actual values for process control, which use the mechanical degrees of freedom to react to the reference variables. The reference variables are common variables that can be represented by drawing specifications, such as geometry and hardness.

Acknowledgement

The research project presented is funded by the German Research Foundation (DFG) – “GR 1818 / 72-3” as part of the Collaborative Research Center SPP2183 – “Property-controlled forming processes” under the project number 424334856.

Funded by

Priority Programme

Project Partners