PROMATE – Process monitoring using a measuring box, AI technology and assisted expansion

The aim of the research project is to develop a universally applicable AI-supported assistance system for setting up measuring systems and monitoring fast-running production processes. In order to keep the requirements for existing infrastructure and expert knowledge low and thus make the technology accessible to a broad field, an application-adaptive measuring box is to be developed.

Funded by

Coordinator: Ciarán Veitenheimer M. Sc.

Duration: December 2024 – November 2026

Funding line: Distr@l Förderlinie 2A: Digitale Produktinnovationen

Motivation

Companies, especially small and medium-sized enterprises (SMEs), are facing the growing challenge of making their production processes efficient and competitive. The digitalization of processes offers the potential to automatically detect critical conditions and initiate appropriate countermeasures through permanent monitoring. The prerequisite for this is the collection of data that contains information about the process status and can be processed quickly. The selection and integration of suitable sensors and models is process-specific and often requires in-depth process knowledge. The required infrastructure is also often a hurdle for companies, which means that the potential of digitizing production processes is usually not exploited. The aim is therefore to develop a system that supports the operator in data acquisition, processing and modeling and places low demands on the existing IT infrastructure.

Approach

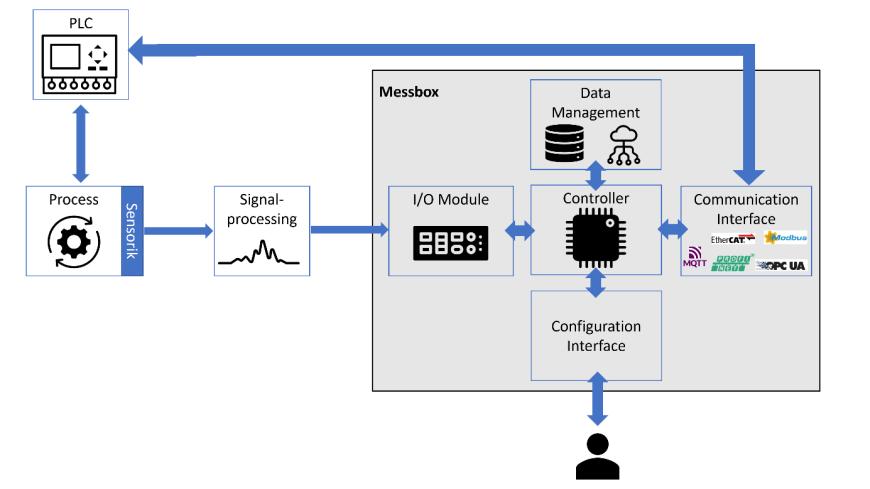

The PROMATE project focuses on the development of an application-adaptive measuring box, which, as a cyber-physical system, covers the entire process from data acquisition and processing to storage. The combination of a hardware platform and AI-supported assistance software enables simple integration into existing production environments without placing high demands on the existing infrastructure. The measurement box uses AI algorithms to support the selection and integration of suitable sensors, and the analysis of the data obtained. Expert knowledge is transferred directly into the software, making it possible for companies without in-house IT or analysis expertise to use it. Particular importance is attached to the generation of data with a high information content, which is especially necessary for monitoring fast-moving production processes. Another key component is the no-code platform, which allows individual adaptations without programming knowledge. This makes the technology particularly attractive for SMEs with limited resources. The automated analysis and monitoring process can thus help to increase productivity, reduce the workload of specialist staff and secure process knowledge within the company in the long term.

Acknowledgement

The PROMATE project is supported by the Distr@l funding program with funds from the State of Hessen. We would also like to thank our partner Data Hive Cassel GmbH.

Network Partner