Demonstration and Transfer Network AI for Forming Technology ProKI-Darmstadt

ProKI is a nationwide demonstration and transfer network for AI in production and is funded by the German Federal Ministry of Education and Research. At the ProKI-Darmstadt center a demonstration and transfer network for applications of artificial intelligence (AI) in the metal industry with a focus on forming technology is being developed and established. The central core of the project is the development and transfer of AI-based applications into the production environment of small and medium-sized enterprises (SMEs) as well as the transfer of competencies in the field of artificial intelligence. The transfer and the imparting of competencies are to be driven forward by an extensive range of services over the duration of the project. In this context, the contents of current research results are conveyed to interested SMEs in a user-oriented and practical manner through expert discussions, live demonstrations, and workshops. In addition, the experts provide concrete support to companies in implementation projects for the application of AI-based applications. In this way, the project reaches a broad user group of companies and accelerates the transfer of AI technologies, especially in the field of forming technology.

Coordinators: Ciarán Veitenheimer M. Sc. | Viktor Arne M. Sc.

| Sven Varchmin M. Sc.

| Markus Schumann M. Sc.

Duration: October 2022 – December 2024

Funded by: Zukunft der Wertschöpfung (BMBF)

Homepage: www.proki-darmstadt.de

Motivation

Forming technology, with more than 200 different processes, forms the backbone of German metalworking industry, both in semi-finished product and component production. Up to now, experience coupled with advanced planning and simulation methods have been the key to successful application. However, two new trends are endangering the long-standing success of German companies in the forming technology sector: On the one hand, the increasing complexity of forming processes, caused by more demanding materials as well as higher flexibility requirements, is pushing the possibilities of experience-based process design and planning with deterministic models to their limits. On the other hand, the personal experience-based knowledge of employees is disappearing as a result of their retirement, with this challenge growing steadily due to demographic change and a shortage of skilled workers. Against this background, AI offers considerable potential to increase the competitiveness of metal forming companies. Despite this potential, the use of AI is currently limited to individual industrial use cases and scientific research projects. In this context, the Scientific Society for Production Technology (WGP) identifies an insufficient transfer of research results into industrial practice, insufficient competencies at the interface between AI and manufacturing technology, and the lack of a methodical procedure model for the integration of AI into industrial applications. The ProKI-Darmstadt research project thus aims to accelerate the transfer of AI technologies into forming technology applications, to impart AI expertise and to provide companies with systematic procedures for successful application.

Approach

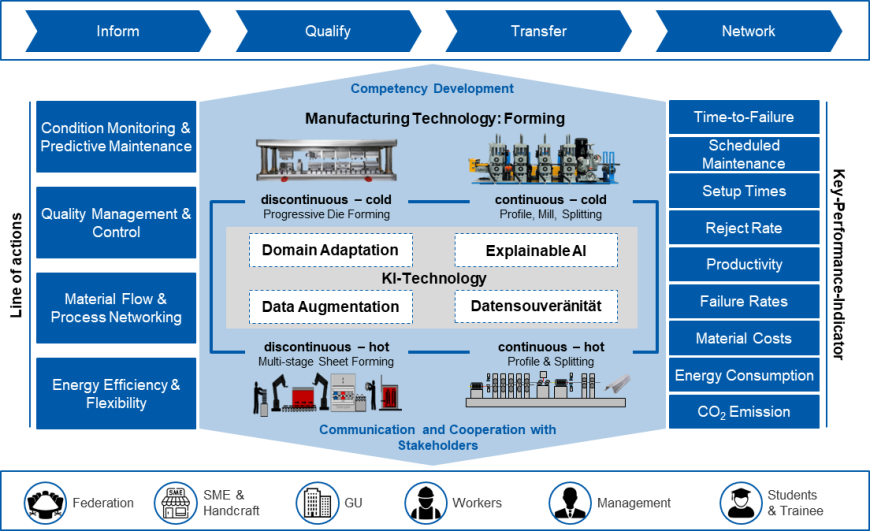

To achieve the project goals, the ProKI-Darmstadt Center is oriented towards the four main areas of action:

- Inform

- Qualify

- Implement

- Networking

The offers are aimed at people with different levels of knowledge and from different areas of the company and differ in terms of the depth of content, thus addressing a broad target group in the companies. Within the framework of the project, four strands of action will be developed, focusing on the topics:

- Condition monitoring and predictive maintenance

- Quality management and control

- Material flow & process networking

- Energy efficiency & flexibility

The main topics are investigated and transferred for competence development in continuous as well as discontinuous processes and for cold as well as hot forming. The companies should be able to measure and improve their various performance targets (key performance indicators) to ensure a future-proof continuation of German production using AI technologies.

Acknowledgement

The ProKI research project is part of the Demonstration and Transfer Network AI in Production (ProKI Network) in the BMBF's funding programme „Zukunft der Wertschöpfung − Forschung zu Produktion, Dienstleistung und Arbeit“. The Institute of Production Engineering and Forming Machines would like to thank the BMBF for funding the project.

Funded by