Excursion to Kinkele GmbH & Co. KG

2018/04/11

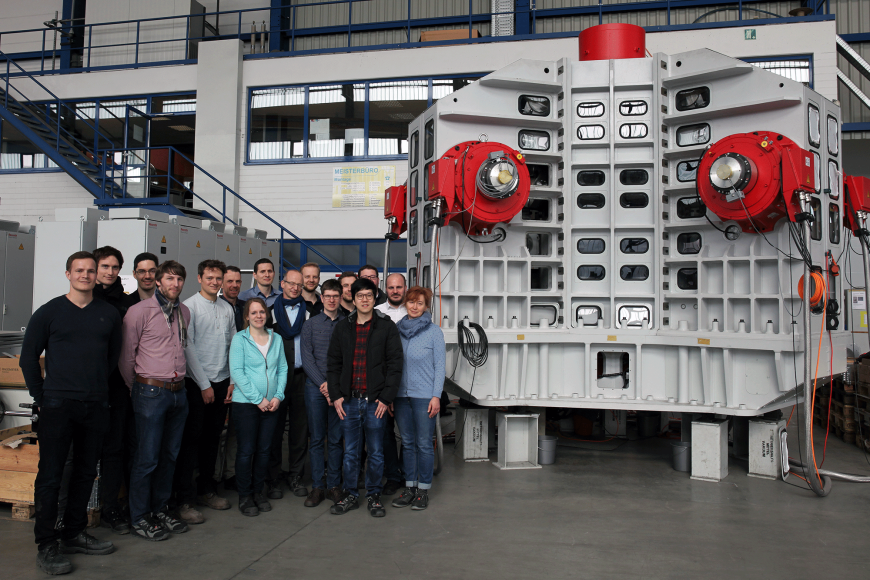

Visit of Kinkele in Ochsenfurt as prelude to the assembly of the lower part of the 3D servo press.

The 3D Servo Press is a multi-technology machine that is characterized by a combination of a force-bound and a pathbound kinematics.

The 3D Servo Press has been under development at the PtU since 2010 and was funded by the German Research Foundation (DFG) as part of the Collaborative Research Centre SFB 805.

Kinkele has been manufacturing the large welding assemblies of the 3D servo press since 2015. Total assembly and cold commissioning also take place there.

The completion of the assembly of the upper part (see figure), which forms the gear unit of the 3D Servo Press, was the occasion for the staff of the PtU to get to know the Kinkele company during a factory tour. This offered the opportunity to experience the functionality of the transmission in reality.

With the assembly of the lower part now beginning, the last assembly section begins before the two large pre-assembled modules – upper and lower part – can be placed on top of each other and assembled. After successful cold commissioning, the 3D Servo Press is to be completed in summer 2018 and then delivered to the PtU.

We would like to thank Kinkele, in particular Mr. Ullrich, Mr. Vogel, Mrs. Höß and Dr. Beck, for the guided tour through the production site as well as the hospitality and the efforts of this excursion.